Choosing the type of hives can seem like a daunting task if you focus on the variety of options used in modern beekeeping. But this is not necessarily the case. Start small, read about the various modifications in this review and this will help you make a choice.

General requirements for bee houses

Whatever model you choose, the general requirements will be the same for any of them. But these requirements can be provided in different ways.

General requirements for any type of construction:

- universal design should be able to expand with increasing size of the bee family;

- the hive must have high-quality ventilation, which provides fresh air and dryness from the inside;

- it is desirable that it retains heat well due to insulation or materials from which it is made;

- the hive should be light enough to be convenient to move;

- useful life - at least 15 years;

- the framework should not lie against the walls; the optimal distance between them and the wall is at least 7-8 mm; frame thickness - 25 mm;

- for production, the use of boards made of soft wood: cedar, fir, spruce, pine, poplar, willow, linden;

- wood should be knot-free;

- permissible wood moisture - not more than 15%;

- corners are joined with waterproof glue and nails;

- the outer part of the hive must be primed with linseed oil and coated with oil paint.

Did you know? Deep in the forests of the Himalayas, the largest honey bee in the world makes hallucinogenic honey from flowering rhododendrons. This honey is so valuable that locals in China and Nepal risk their lives in order to harvest and sell it to rich and curious tourists.

The most famous designs

You have many hive options to choose from, including some very exotic and interesting specimens. But only about 5 main types of hives are actively used. Each of them has its advantages and disadvantages. As in most cases, beekeepers advise exactly the type of hive that they use as the only correct one. Therefore, it will not be superfluous to get acquainted with each of them.

Dadanov hive

The original Dadan hive is a single-hull vertical structure with 10 frames measuring 10½ × 18 inches (26.7 × 45.7 cm). It is copied from the Quinby model for 11 frames and is its practical counterpart. Therefore, Dadan himself called the model Quinby Dadan. In 1920, a modified 12-frame Dadan was released. Therefore, now you can meet various options for the device of the bee hive, which includes 10 to 12 frames.

The uniqueness of the technology for developing such a hive lies in the fact that in a horizontal section it is a square. And sotoramki in it can be placed both horizontally and vertically. To do this, the folds are placed on all four walls. Ule Dadan is not insulated, therefore, in spring it needs to be insulated, especially in the northern regions to ensure the rapid development of the bee family. To do this, a special mat is laid on the ceiling of the nesting frames and the sidewalls are insulated.

As part of the hive:

- bottom;

- hull with letok;

- store extension for frames;

- the roof is pent;

- arrival board;

- nesting frames;

- shop frames;

- plug-in board.

Did you know? Unlike most products, honey does not deteriorate over time. The oldest known honey specimen found in the ancient Egyptian tomb and dated about 3,000 years ago is considered completely edible.

Alpine

Roger Delon is a commercial beekeeper from the Vosges region (France). He took Varre's hive as the basis of his design. Its principle of maintaining heat in the nest by adding new boxes when the weather changes, is the basis of the new design.

Roger Delon is a commercial beekeeper from the Vosges region (France). He took Varre's hive as the basis of his design. Its principle of maintaining heat in the nest by adding new boxes when the weather changes, is the basis of the new design.

In the context of the hive is also a square. The founder of the design, Abbot Emil Varre, considered it especially important to maintain the principle of outer space in the hive. It is understandable to bees in a natural setting. The inside should be close to the structure that wild bees create inside the tree.

The size of the structure is reduced in order to bring it closer to the hollow. New boxes are added below existing ones, and existing ones are moved up in the stack. This is convenient for those who have problems with lifting a lot of weight.

To support the vertical frames, Varre used simple trims covering the top of each box. Therefore, the bees conduct their construction in natural conditions - from top to bottom. At the top of the structure is a cover for placing mats. They absorb condensation that bees can generate. And this is very important in winter, so as not to cause moisture accumulation from temperature extremes.

Characteristics of the hive:

- inner box size 30 × 30 × 21.5 cm;

- the maximum height of the hive in the summer is 1.5 m;

- walls with a thickness of at least 3 cm with external painting and obligatory application of drying oil or other primer before painting;

- floor tilted down to the front;

- 45-degree landing board with a 30 cm wide entrance; bees from the hive take off from this board or return to it with nectar.

Thick walls, a sloping floor with a full-sized entrance that can cope with any condensation, make the Delon alpine hive more suitable for cold climates. The use of frames that do not impede the tight sealing of the socket in the upper part or bypassing in some places on the sides of the box is also a good design feature.

There are no ventilation grilles or dividing in this design. The scheme of movement of air masses is as simple as possible: the air flow is heated and saturated with carbon dioxide when moving from the notch, reaching the top point of the structure, it turns and returns to the exit.

There are no ventilation grilles or dividing in this design. The scheme of movement of air masses is as simple as possible: the air flow is heated and saturated with carbon dioxide when moving from the notch, reaching the top point of the structure, it turns and returns to the exit.

- Beekeepers noted the following design advantages:

- families in it develop faster;

- collection of nectar and pollen is 2-3 times higher than in other systems;

- due to its simplicity, the system is understandable to the beekeeper and easy to maintain;

- the hive contains much less wood, and it is slightly lighter than the Dadan hive;

- it is easy to carry, even with honey it weighs up to 16 kg;

- the reduced size of the frames allows you to solve the problem of honey collection in conditions of a weak bribe;

- polypropylene mat is used for winter warming and this is enough to maintain the temperature.

Did you know? Bees live not only in groups. A wooden bee or a carpenter bee is a solitary insect and it does not create honey. Of the several thousand species of bees, only 7 are melliferous.

Ruta

The hive of Ruth or Langstroth is the most famous construction. This is the grandfather of all the hives, which was invented by the Rev. L. L. Langstrot in 1852. Of course, the design of the hive has changed somewhat in recent years. It has become modular, expandable and convenient for the beekeeper. The main modification is a convenient vertically hanging frame. The design also reflects a space convenient for a bee in a natural environment.

Langstroth's innovation was an opening hive with movable honeycombs. But the contribution of Ruth is that he made the design multi-hull. The house has become not only revolutionary, but also more convenient for use in large apiaries.

- Advantages or features of the hive of Ruth:

- maximum proximity to the natural habitat of the bee - hollow;

- convenient cleaning of the house - just replace the bottom with a clean one;

- good family development;

- convenient pumping of honey;

- adjustable height design depending on the season and the development of the bee family;

- 3 depth boxes are available: deep, medium and shallow, and 2 width options for 10 or 8 frames.

Important! Hive construction Langstrota-Ruta is standard and many accessories and components are produced for it. You can easily assemble a system for your bee colonies.

The size of the structure is 40 × 46.2 × 24 cm. The photo frames are 43 × 23 cm. Letkovye slots can be adjusted from 9 to 23 mm. The preferred Langstroth configuration is still an 8-frame, reduced-weight design in which all parts are interchangeable. Shallow crates are usually used for nesting feeders or other accessories, rather than expanding the hive. This is a great option for those who want to have a small apiary with several hives.

Cassette

Domestic beekeepers also do not stand still, especially since the practice of beekeeping in our country has a very long tradition. The cassette type hive was invented by the Sorotkin brothers. The system is designed to facilitate the transportation of beehives when changing the place of honey collection after the main honey plant has waned. The design is a modular pavilion on wheels. It can be of any size and can be transported by any car. It is estimated that about 24 bee families will fit in a trailer of a passenger car.

Beehives are combined in 4 sections in 2 rows, between them there is space for working with bees. Sections consist of drawers. Each of them has its own door. In order to push the drawer, there are guides from the bars. The front wall has a notch, and at the bottom of the case there is a lettered gap.

The shape of the design also resembles a cabinet, which consists of individual drawers. The dimensions of the cassette hive can be any - depending on the size of the trailer. They depend on how many families you need to accommodate. The number of frames can also be any.

Basic design requirements:

- Between adjacent cassettes or drawers there should be about 10 mm of clearance. If the gap is larger, then the bees begin to form honeycombs here, and if it is smaller, then they will seal it with propolis.

- The space of each bee colony should be separate.

- The thickness of the walls of the structure is not less than 7 mm.

Important! It is not recommended to make hives from resinous boards. Resin can give a specific flavor to your honey.

- True, this design has significant disadvantages:

- insufficient isolation of families leads to the rapid spread of infections and death of bees;

- crowding of the uterus is also a problem;

- a trailer with beehives is a rather bulky design, and apiaries are placed away from good roads, so there may be a problem with transporting it from the installation site.

Of the positive aspects, beekeepers note the convenience of using a cassette system for stationary placement of hives in the southern regions. Their maintenance is minimized and does not require physical effort. In addition, they do not need to be additionally insulated or protected from rodents. In the construction of such sizes, rodents are instinctively afraid to go.

Ukrainian sunbed

A somewhat non-standard, but sufficiently used construction is the “Ukrainian beehive-lounger”. In shape, it resembles a chest and does not have collapsible parts. The hive is designed for 22 tall frames measuring 30 × 43.5 cm.

Design Features:

- the summer is located on the side of the hive;

- suitable for keeping 2 bee colonies (you can insert a partition to divide the space);

- hive size 83 × 44 × 60 cm;

- the length of the upper and lower grooves is 20 cm; the height is 1.2 cm.

The construction is simple enough to care for. Beehive lounger is convenient for beekeepers involved in breeding bee families.

- Among the design flaws, beekeepers note:

- bulkiness;

- inconvenience of transportation;

- complicated air exchange in the cold season during wintering;

- inconvenient location of the socket (vertical).

Important! Studies prove that the activity of bees depends on the plane of the nest. And in its horizontal arrangement, they are more active.

Multicase beehive

The multi-shell, bezfaltsovy hive is a synonymous name for the Langstroth hive. The design consists of several cases, shop extensions for honey, a lid, a roof cover for insulation for the winter, a bottom, a separation grid, and a stand. The design is based on the idea of maximizing the home for bees to their natural habitat - a hollow. It can consist of 5-6 buildings or 3 buildings and store extensions. In each case, 10 photo frames with a size of 43 × 23 cm are placed.

- Advantages of the multi-hull, non-bale hive:

- easy assembly;

- interchangeability of elements;

- a large assortment of components in stores, as the hive has standard sizes.

This design is not recommended for beginners due to the fact that it is designed for a large apiary and a large honey collection. In addition, the transportation of such structures with honey can be somewhat difficult.

Did you know? M & amp; Ms candy advertising company claimed that "Chocolate is better in color." But beekeepers in the north-eastern region of Alsace do not agree with this. After all, their bees produce blue and green honey, collecting sweet waste from a biogas plant, the company Agrivalor, a manufacturer of sweets.

Characteristics of the hive:

- internal size 45 × 37.5 × 25 cm;

- folds located on all walls allow you to install frames horizontally or vertically;

- on the sides there are recesses-handles for transfer;

- wall thickness - 35 mm.

How to make evidence yourself

If you think that you can make hives with your own hands, then it is difficult to disagree with this. Indeed, with the availability of quality materials and the knowledge of the dimensions of what you need, you will be able to make houses for your bees. But if you are not sure, try to make a model out of paper or draw a drawing and calculate the possible labor costs. At the same time, keep in mind that it should be convenient for bees to dwell in the hive, and you should collect honey with the least difficulties.

Materials and tools you need

For work you will need:

- workbench for cutting wood;

- tool for planing boards;

- plane;

- measuring and marking tool (levels, tape measure);

- drill for drilling holes;

- small 5/8-inch nails;

- wood;

- wood glue;

- drying oil;

- paint for applying an external coating.

Despite the emergence of many new building materials, beekeepers use wood. They are more natural for the bees themselves. Of the new materials, foreign manufacturers recommend expanded polystyrene. Houses made of this material are extremely warm and comfortable for wintering. But they need to be well fixed, since strong winds can overturn these lightweight structures.

Important! Use a beehive board from any soft wood species. It is inappropriate to use plywood or fiberboard because of their susceptibility to atmospheric precipitation and deformation from moisture.

Dimensions, drawings and diagrams

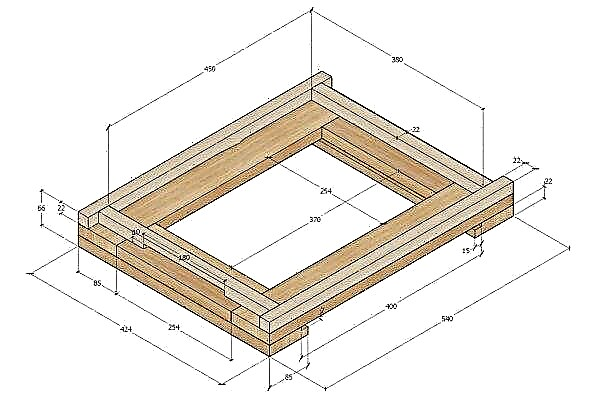

Take the hive of Dadan as a basis. First you need to make a case. This is a wall construction without a bottom. It will accommodate the framework. The internal size is 45 × 45 × 34 cm. The thickness of the board is 3.7 cm. The case can accommodate 10 nesting or 20 magazine frames. The socket frame is designed to form honeycombs.

Dimensions of the nesting frame (length x width x thickness):

- lower bar 41.5 × 2.0 × 1.0 cm;

- side strips 22 × 3.7 upper width × 2.5 lower width × 1.0 cm;

- upper bar 47.0 × 2.5 × 2.0 cm;

- the shoulders of the upper bar - thickness 1.0, depth 2.75 cm.

And you will also need to craft:

- hinge board;

- store extension - it is necessary to increase the family;

- roof cover for fixing the insulation; size 53.5 × 50.5 × 9 cm, board thickness 1.5 cm;

- the ceiling, which is assembled from boards with a size of 47.8 × 8 1 cm;

- a roof (may be single-pitch, gable or flat); strapping height 10.5 cm, side wall length 58.5 cm, end - 53.5 cm; board thickness 1.5 cm;

- an insertion board for dividing the space of the hive; size 45 × 32 cm;

- extendable or stationary deep bottom of the structure; size 54 × 48 cm;

- sectional frames for honey.

Did you know? To get one teaspoon of honey, you need at least eight bees.

Step-by-step instruction

Creating a hive consists of 2 main operations: the preparation of parts and assembly of the structure. You can also purchase ready-made lumber, which remains only to finalize and assemble the structure.

Material intended for work must be dry and prepared for work. Otherwise, you will not be able to accurately maintain the size and after drying, deformations of the finished structure will occur. Choose wood without defects and knots. Knots with a diameter of more than 30 mm are allowed if there will be no more than 2 pieces per part. Allowed wood moisture level - 15%.

Production Instruction:

- Get all the materials. Keep in mind that buying cheap supplies will not only reduce the useful life of the hive, but can also harm bees (and honey).

- Use raw wood — usually pine or cedar.

- None of the boxes have a bottom, so you just need to buy enough wood to create side walls.

- Some components, such as frames and an outer cover, are not easy to manufacture and you better buy them.

- Make the case, store extension, roof, bottom.

Video: making the hive body

Housing

The housing is a rectangular structure for placing frames, which consists of side walls. In it you need to make a notch, which can be upper or lower. For the lower, the front wall should not reach the intersection with the lower element by 1.5 cm. The upper notch is a round hole with a diameter of 25 mm 7 cm from the upper edge.

Did you know? Bees control the transparency of honey by flapping wings at the ventilation points in the hive at different speeds to control the evaporation of water.

Roof

The roof can be single-pitched, gable or flat. The slope is possible due to the fact that the front part of the harness is higher than the rear in height. You can cover the hive with roofing material, galvanized iron or other material.

Below, under the cover, there is a roof cover, which is a board rectangle without a bottom. It contains warming mats, feeders and drinking bowls. When transporting the beehive, a metal mesh is placed in the under-hood, which helps air exchange. The ceiling itself is mounted from separate boards. They are collected using strips. The ceiling will be laid over the upper bars of the honeycomb.

Bottom

Take your preferred wood and create a rectangular base measuring 54 × 48 cm. You can assemble it from several boards. Make sure the board is at least 2.5–3 cm thick. Then take 3 planks and nail them from 3 sides. On the 4th side, make a protrusion so that you can attach the arrival board. If the bottom is not extendable, then it is nailed to the body. But if it moves, then you need to install the skids so that you can move it relative to the body.

Did you know? Bees can seal the hive on their own. To do this, they create propolis. This resin is a natural sealant that protects their house from harmful microorganisms and has anti-varratic properties.

How to place a beehive in an apiary?

Place for installation must be prepared in the fall or spring. Pick a site near the place with blooming honey plants. Bees can travel long distances, but still, so you will know for sure that you will have honey. People and cars can interfere with bees. Therefore, hives are placed away from highways and crowded places.

Each house needs to be put on a special stand. Be sure to expand it so that the letok is located in a southwestern direction. Letters should be parallel to each other. This eliminates the hassle between neighboring families.

It is desirable that the hives are partially hidden in the shade of the trees. So they will overheat less and bees do not need to spend energy on cooling their homes. If there are no trees nearby, plant corn or a sunflower near the hives. These tall plants will cover the apiary when the hottest period comes.

If possible, then install the hives in the same place where they were located in the previous season. Bees well remember the road and the location of honey plants. They will not need to conduct reconnaissance of the terrain and explore the territory again. Hives can be placed in rows or in groups of several pieces.

In conclusion, we can add that, choosing standard types of hives, you can count on the fact that you can always buy additional elements to them. But on the other hand, self-made differ in improved structural solutions. And this is the main advantage of creating a house for bees with their own hands. In addition, such a house may be cheaper than purchased.