Polycarbonate coating is often used to build a greenhouse with your own hands, since the assembly of such a design does not require specific professional knowledge. Polycarbonate is lightweight and has excellent insulating properties, but is expensive, easily damaged and melts under the influence of high temperatures.

Design Features of the Prefabricated Greenhouse

The polycarbonate greenhouse must be durable and prevent the entry of cold air from the environment. Optimal lighting is provided throughout the construction area - this makes it possible to create optimal conditions for the growth of various vegetables, fruits or flowers. If necessary, the structure is supplied with water to provide watering. It is also necessary to provide ventilation holes.

Pros

Polycarbonate is very popular as a material for the manufacture of greenhouses, because it is lightweight and durable.

- It consists of small honeycombs filled with air, due to which it has a number of such advantages:

- Allows you to create any design and shape, because it is very flexible.

- It is a refractory material: it does not burn under the influence of fire, but only melts.

- Protects plants by trapping and reflecting harmful ultraviolet rays; at the same time, it allows sunlight to pass through, which has a positive effect on plants.

- Suitable for growing plants in the winter and provides heating savings. Due to the greenhouse effect, polycarbonate reduces heat loss.

- You can create such a greenhouse with your own hands, since installation work does not require much effort, because the material is simply cut, glued and drilled.

- Simplicity in the design of windows of openings and doors.

- Durability during operation.

Minuses

The main disadvantages of greenhouses made of such a material are its high cost in manufacturing compared to film or glass structures. This is due to the cost of polycarbonate and the need to build a more expensive (due to reinforcement) frame for the greenhouse.

In addition, under the influence of very low or high temperatures (outside the range of -50 ... + 120 ° C), polycarbonate can change its size, as well as distort. The greenhouse cover is easy to scratch, because of this, polycarbonate will transmit light unevenly.

Did you know? For the first time, the idea to grow greenery indoors arose in China, about 5,000 years ago. Presumably, such plants were initially used for medicinal purposes, and only later - for decorative ones.

Choosing the best greenhouse option

There are such types of polycarbonate folding greenhouses:

- Arch-shaped. They look like a semicircular long tunnel. Due to this, precipitation does not linger on its surface, and the structure evenly transmits sunlight.

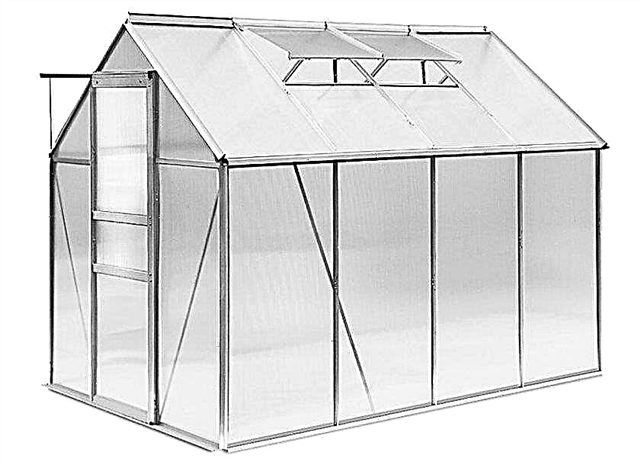

- In the shape of a tent. They have a square or rectangular shape.

The constructions of the second type are divided into several subtypes depending on the type of roof:

- With one ramp. They are an extension to the wall of the house, due to which it is possible to reduce the amount of necessary material.

- With two ramps. They have two slopes and are distinguished by high material costs and massive construction.

- Polygonal. Complex greenhouses during installation, but have an attractive appearance.

- Teardrop shaped. They are able to build only professionals.

Dimensions

In areas with a small area, it would be advisable to build greenhouses of small size. They are easy enough to collect or move to another place. It is also convenient to use a folding structure, removing it at a time when plants are not grown. Small greenhouses are convenient to care for and they are much cheaper to build than large structures.

Important! A large greenhouse must have a foundation, which will give the structure strength and help withstand its significant weight.

However, it is important to consider that only vegetables and fruits with the same development conditions can be grown in such greenhouses, because it is difficult to create a favorable microclimate for various crops in a small room. In small greenhouses, ventilation is needed, which will protect the plants from overheating associated with a small area.

A large greenhouse can be divided into two zones and grow several crops there

A large greenhouse can be divided into two zones and grow several crops there

Coating

Polycarbonate greenhouses can be single-layer and double-layer. Greenhouses with two layers of polycarbonate are rarely installed, since this is a very time-consuming process, requiring large material costs. And, besides, even one layer of polycarbonate will make the greenhouse airtight.

There are several types of polycarbonate film:

- Cell. It consists of two layers of material, between which there are jumpers. This design creates small spaces filled with air.

- Fibrous. Such polycarbonate has a wavy shape and is resistant to damage.

- Monolithic. It is a continuous sheet of material and has a low weight, therefore, it has advantages in the installation of the structure.

How to assemble a greenhouse with your own hands

For self-assembly of a polycarbonate greenhouse, it is necessary to first prepare the foundation around the entire perimeter of the future structure. This will give rigidity and strength to the lightweight greenhouse design. The assembly of profiles begins with the basics, having previously studied the drawings of the future greenhouse. Next, the surfaces of future walls and room corners are fixed. All parts are fixed with jumpers. To cover the greenhouse, it is necessary to fix the polycarbonate sheets in the holes of the supports, which are not yet involved. Additional fixation is facilitated by staples throughout the frame. It is important to treat the joints of the polycarbonate sheets with the grooves with a special sealant.

To cover the greenhouse, it is necessary to fix the polycarbonate sheets in the holes of the supports, which are not yet involved. Additional fixation is facilitated by staples throughout the frame. It is important to treat the joints of the polycarbonate sheets with the grooves with a special sealant.

Foundation selection

When installing a polycarbonate greenhouse, you must first select a place and fill the foundation. It will make the structure more resistant to mechanical damage and help the greenhouse to serve more than one season. To fill the base of the greenhouse, a cement solution is used, which also includes sand and gravel using a mesh or reinforced rods, which gives the structure rigidity and strength.

Previously, in the place of the future greenhouse, they dig a trench around the perimeter of the future greenhouse, about 15–20 cm in depth, and formwork is used for the ground part. They construct a structure from factory blocks, the height of which should be at least 15 cm.

The ends of the structure for a more thorough connection are fixed with self-tapping screws and are attracted to each other as much as possible - this helps to prevent the formation of gaps through which the solution will leak. The thickness of the foundation should be slightly larger than the bottom profile.

You can build a greenhouse out of polycarbonate and without a foundation, but it will not differ in reliability and durability. This design is only suitable for small greenhouses.

You can build a greenhouse out of polycarbonate and without a foundation, but it will not differ in reliability and durability. This design is only suitable for small greenhouses.

Frame assembly

For the frame of the greenhouse, you can use aluminum or plastic profiles. Plastic is more suitable for small structures, because the material is not able to withstand a large mass of the structure; however, at the same time, it better ensures the tightness of the greenhouse. Aluminum frames are used for all types of structures and are equipped with special grooves that withstand dense casing. Greenhouses on a metal frame are more durable and withstand significant mechanical damage.

Installation of a polycarbonate greenhouse includes the following steps:Important! Before sheathing, the frame is not assembled tightly, since it is still necessary to mount a polycarbonate coating in the profiles.

- Unfolding separately all the structural details and a careful study of the drawings.

- Installation of a base consisting of bottom profiles.

- The installation on a cement base of the support of wall surfaces and corners.

- Connection and firm fixation of all parts with jumpers.

- Rigid fastening of the main frame profiles together.

- Mounting of the ridge and vertical support.

- The establishment of additional support rafters that are screwed to the ridge.

Video: Gathering the frame of the greenhouse

Frame cladding

Polycarbonate sheets are mounted in the holes of vertically standing supports and tightly screwed to their base with self-tapping screws. They are also further strengthened by uprights on the diagonal, which are inserted into the empty grooves of the support. After fixing the polycarbonate, a special protective film is removed from it.

Additional fixation of the roof to the frame of the structure is carried out using metal brackets. At the junction with the frame, the polycarbonate is impregnated with a sealant. This makes it possible to eliminate even small remaining holes.

Additional fixation of the roof to the frame of the structure is carried out using metal brackets. At the junction with the frame, the polycarbonate is impregnated with a sealant. This makes it possible to eliminate even small remaining holes.

Tips for operating and maintaining a greenhouse

At the end of the season, the soil of the greenhouse is dug up and fertilized with mineral superphosphate or calcium sulfate. After the end of the season, when the crop is harvested, it is necessary to clean the land inside the structure from weeds and the remains of cultivated plants. It is also recommended to remove the top layer of chernozem, about 5 cm.

It is also desirable to disinfect the greenhouse using the gas method; It is applicable in a polycarbonate greenhouse because it is leakproof. After disinfection, the greenhouse is left closed for three days, which guarantees the death of all parasites in the soil.

Did you know? The first greenhouses invented in Djealous of Rome, looked small wagons that were in the daylight in the daylight and transported to special rooms with heating at night. This allowed Roman gardeners to experiment with growing vegetables and fruits year-round.

In winter, it is recommended to remove the polycarbonate coating. When using greenhouses made of polycarbonate, the following rules must be adhered to:

- Do not make a fire near the greenhouse, since such material quickly melts under the influence of high temperatures;

- it is necessary to wash the structure without adding aggressive detergents and abrasive - these substances damage the coating that protects against ultraviolet radiation;

- Before use it is necessary to check the integrity of the coating and the stability of the frame.

A polycarbonate greenhouse is easy to make with your own hands, it is convenient to use and durable, because this material is durable and reliable, as well as significant heat-insulating properties compared to film and glass analogues. A polycarbonate greenhouse is able to create the most favorable conditions for the growth of various plants, therefore it is suitable for both professionals and gardeners.